Contents

2. Procedure and control description

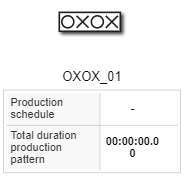

The Schedule box is an object for generating orders for processes in a defined product sequence by means of production patterns.

Thus, the Schedule Box transmits the production orders to processes via information flow, which then process them accordingly.

In contrast to a connection with the PPS, the orders are generated locally in the Schedule Box without a link to customer orders or MRP calculations.

A predecessor connection with the PPS (PPS to Schedule Box as information flow) is allowed for descriptive purposes, but has no influence on the simulation implementation in the background.

Currently only one information flow successor (processes other than rework) is allowed on the simulation side.

2. Procedure and control description

In the Schedule Box, production quantities or production durations are defined sequentially for each product as production patterns in a table structure (either production quantity or production time per entry).

These are processed by the connected processes. For each controlled process this is a "pulling system" for orders, i.e. the next entry of the production pattern is queried as an order by the process when the local order queue reaches 0. This means that no order queue can be built up in the process. If a sample entry is ordered with a quantity, it is rounded to the lot size using the regular incoming orders in the process.

If a time limit is set for a production sample entry, order units of 1 are passed on per query for a new order from the connected process until the production time limit is reached (this refers to the working time of the process).

If a total duration is also defined for the production pattern, the production pattern entries with a quantity specification are also passed on in orders with a quantity of 1.

This is to ensure that either the entire production pattern or the lines with a production duration specification do not lead to an over-order of basic parts from the producing process when orders have to be interrupted.

At least one entry is required to define a production pattern. Entries for the same product and also the same product itself can be defined directly after each other.

Figure 1 - Schedule box |

|

See chapter Possible connections to objects.

© SimPlan AG - Hanau District Court, Commercial Register (Part B) 6845 - info@simplan.de - www.simplan.de/en