The following chapter describes the static key figures that are automatically determined for process and customer objects and visualized below the object symbols.

The definitions of the static key figures listed in this chapter can be found in Calculation static key figures.

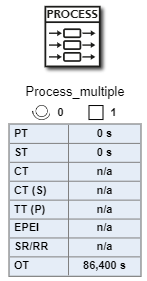

Static key figures for process objects

Object |

Key figure |

Description |

Figure 1 - Process object |

PT |

Process time indicates the dwell time of a product within a process. KPI calculation includes cycle time, transfer quantity, lead times (Process Lead), and station capacity (Process indexed) |

ST |

Setup time provides overview on the time required to setup the machine when there is a change in the product family to be produced. |

|

CT (Cycle time) |

Time interval between 2 exiting parts from a station within process object. For process multiple CT is the overall cycle time of the parts leaving the process multiple object as a whole and not individual station within the object |

|

CT(S) |

Relevant only for process-multiple object. It provides an overview on the cycle times of individual stations within process multiple |

|

TT(P) |

Tact time (Process) provides information regarding the required rate at which individual process have to produce parts in order to meet customer demand. Depending on customer demand, calculated through XPB along the material flow path -> individual demand per station and available time in shift calendar |

|

EPEI (Every Part Every Interval) |

Depicts how long a process takes to manufacture all defined products (or product variants) within a process. It also indicates the flexibility of a process to switch between variants within a product mix. |

|

SR/RR |

Scrap rate (SR) provides information regarding the percentage of parts to be scrapped or deleted post processing within the station. Rework rate (RR) provides information regarding the percentage of parts which are found to be defective and undergoes rework. If rework within station is selected, then the rework happens within the station with and additional waiting time of rework time for the part. If the rework is external, then the parts to be reworked would be moved to external rework station. |

|

OT |

Overall time (OT) represents the overall available working time without inclusion of unplanned time (no shift defined) and pauses (within shifts) of the process object in seconds. It is dependent and calculated based on the shift calendar input provided for individual process object (on the reference day). |

Static key figure for customer object:

Object |

Key figure |

Description |

Figure 2 - Customer object |

TT (24h) |

The average tact time with which an upstream VSM must produce to cover the average daily (24h) product demand of the customer. |

TT(OT) |

The average tact time with which an upstream VSM must produce to cover the average daily product demand of the customer with ordering within the shift calendar (OT, reference day) of the customer. When 24h shift calendar is considered at the customer then TT(OT) will be same as TT (24h) |

|

DD(d) |

Daily demand requested by the customer to the upstream VSM. DD(d) is dependent on the available time for which the customer orders based on shift calendar (reference day). |

© SimPlan AG - Hanau District Court, Commercial Register (Part B) 6845 - info@simplan.de - www.simplan.de/en