Contents

1. Brief description

2. Procedure and control description

3. Parametrization

4. Connection types

1. Brief description

In principle, a lead process behaves like a simple process. The difference is that a throughput time is defined in addition to an actual cycle time.

2. Procedure and control description

The information about the product to be processed arrives via a production order. A PPS, a subsequent supermarket or a Kanban object create production orders.

The process orders the basic products needed for the production order from a previous storage, supermarket or supplier.

Often processes are not only charged with production orders from only one production line, but also for production orders from other production lines.

Using the ForeignOrder object, these shared resources can be projected onto the respective process object.

Physically you can imagine this object as a continuous furnace, where the products need a certain time to come from the inlet to the furnace to the outlet from the furnace (cycle time).

But every x seconds parts come out of the furnace, where x is the actual cycle time. If the cycle time is equal to the actual cycle time, the object behaves like a simple process.

Furthermore, a distinction can be made as to whether the respective process contributes to increasing the value of the finished product or not.

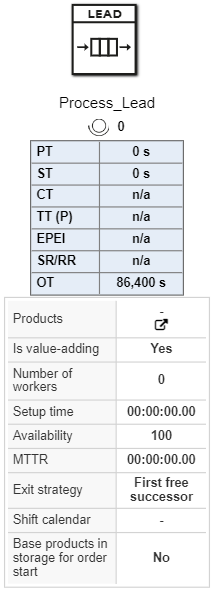

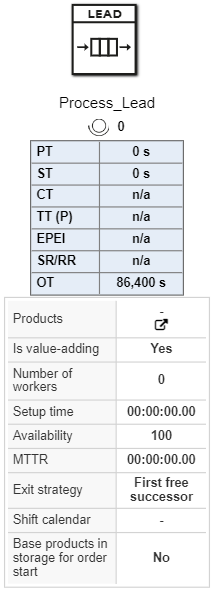

Figure 1 - Procedure and control description

3. Parametrization

Figure 2 - Process (Lead)

|

Process Parameter

|

Required

|

Description

|

|

no

|

Name of the object

|

Products

|

no

|

Products of the object

|

|

no

|

Determining whether a process contributes to increasing the value of a product

|

|

yes

|

Number of assigned workers per process

|

Setup time

|

yes

|

Time required for an object to prepare for an upcoming product

|

Create setup matrix

|

no

|

Opens a new view to create a setup matrix

|

|

yes

|

Reliability (in %) with which an object operates without interference.

Percentage only refers to the working time status (machine is not disturbed during unplanned, paused, waiting or setting-up)

|

MTTR

|

yes

|

Meantime to Repair: Time required to repair a malfunction

|

|

yes

|

Logic according to which the products leave the object

Available modes:

•Cyclic (blocking)

•Start at successor 1 (cyclic, non-blocking, each test with start at first successor; corresponds approximately to "overflow control")

•First free successor (cyclic, non-blocking, start at last successor + 1)

•Lowest occupancy (lowest relative capacitive occupancy; without paused and disturbed parts, weighted by time) |

|

no

|

Allocation of working hours and rest periods

|

|

no

|

Determining whether a base product is in storage for order start or not

|

|

no

|

Custom notes and annotations

|

Product Parameter

|

Required

|

Description

|

Product

|

yes

|

Product to be processed

|

Base product

|

yes

|

Product required to manufacture selected product

|

|

yes

|

Number of basic products required

|

|

yes

|

Quantity of products produced

|

Lead time

|

yes

|

Time between entry and exit of an object

|

Planned cycle time

|

no

|

Average planned cycle time per day

|

Cycle time

|

yes

|

Time interval between two products (independent of lot size)

|

Transfer quantity

|

yes

|

Required quantity of products before transfer (regardless of lot size)

|

|

yes

|

Probability (in %) of marking products for rework. Selected products are processed at the first possible station

Rework can be done in the station itself or at the next junction for rework (corresponding edge).

A part is either scrap or rework at the end of a machining operation, i.e. a part that is to be reworked is not destroyed in the same station ([percentage good parts +] percentage scrap + percentage rework)

|

|

yes

|

Probability (in %) with which products are marked as unusable. Selected products are deleted immediately after processing

A part is either scrap or rework at the end of a machining operation, i.e. a part to be destroyed is not reworked in the station

([percentage good parts +] percentage scrap + percentage rework)

|

|

no

|

Position of the order in the order list. The higher the priority, the earlier the order is processed.

|

|

4. Connection types

See chapter Possible connections to objects.

© SimPlan AG - Hanau District Court, Commercial Register (Part B) 6845 - info@simplan.de - www.simplan.de/en