This result section specifies an Overall Equipment Effectiveness (OEE) for processes (simulation time and operating time) and for the whole system (simulation time).

Contents

1. OEE (simulation time and operating time) for Processes

2. OEE (simulation time) for whole system

Figure 1 shows an overview of the individual distributions of the key figures Equipment Effectiveness and Overall Equipment Effectiveness

Figure 1 - OEE (Machine / System) overview

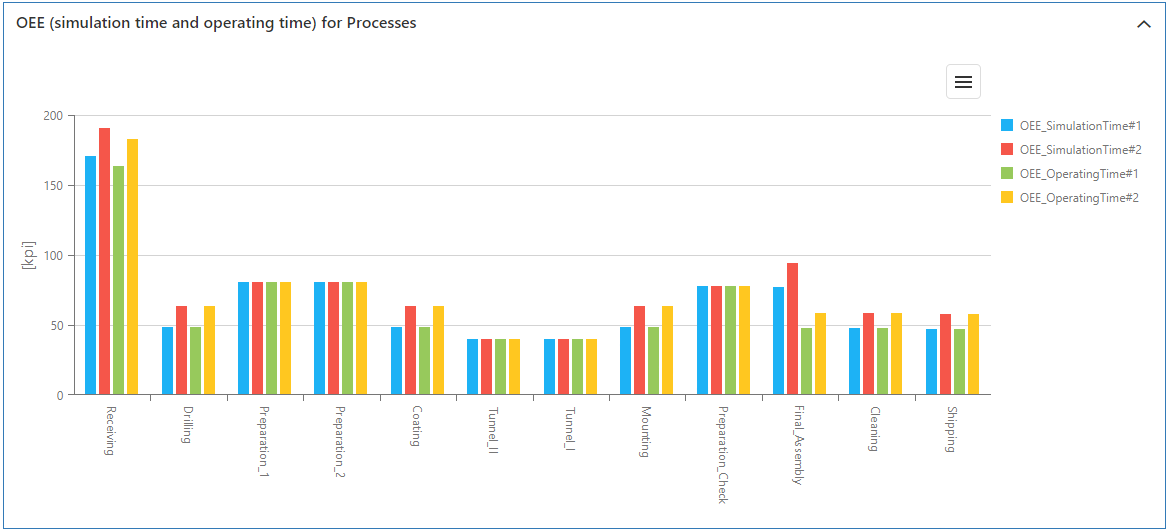

1. OEE (simulation time and operating time) for Processes

The EE per process object uses the simulatively determined number of good parts (IO) in the product with the planned cycle time (process parameters), related to the operating time of the process.

The OEE is related to the total simulation time.

Figure 2 - EE and OEE for Processes

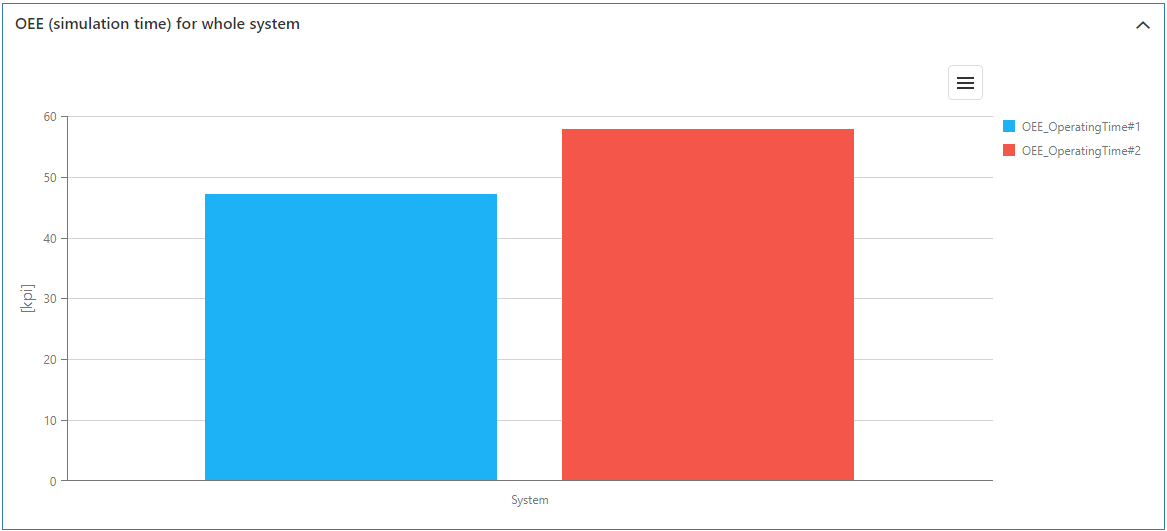

2. OEE (simulation time) for whole system

The OEE per system uses an average customer cycle based on the planned cycle time.

Figure 3 - OEE for System

© SimPlan AG - Hanau District Court, Commercial Register (Part B) 6845 - info@simplan.de - www.simplan.de/en